Energy Pioneers

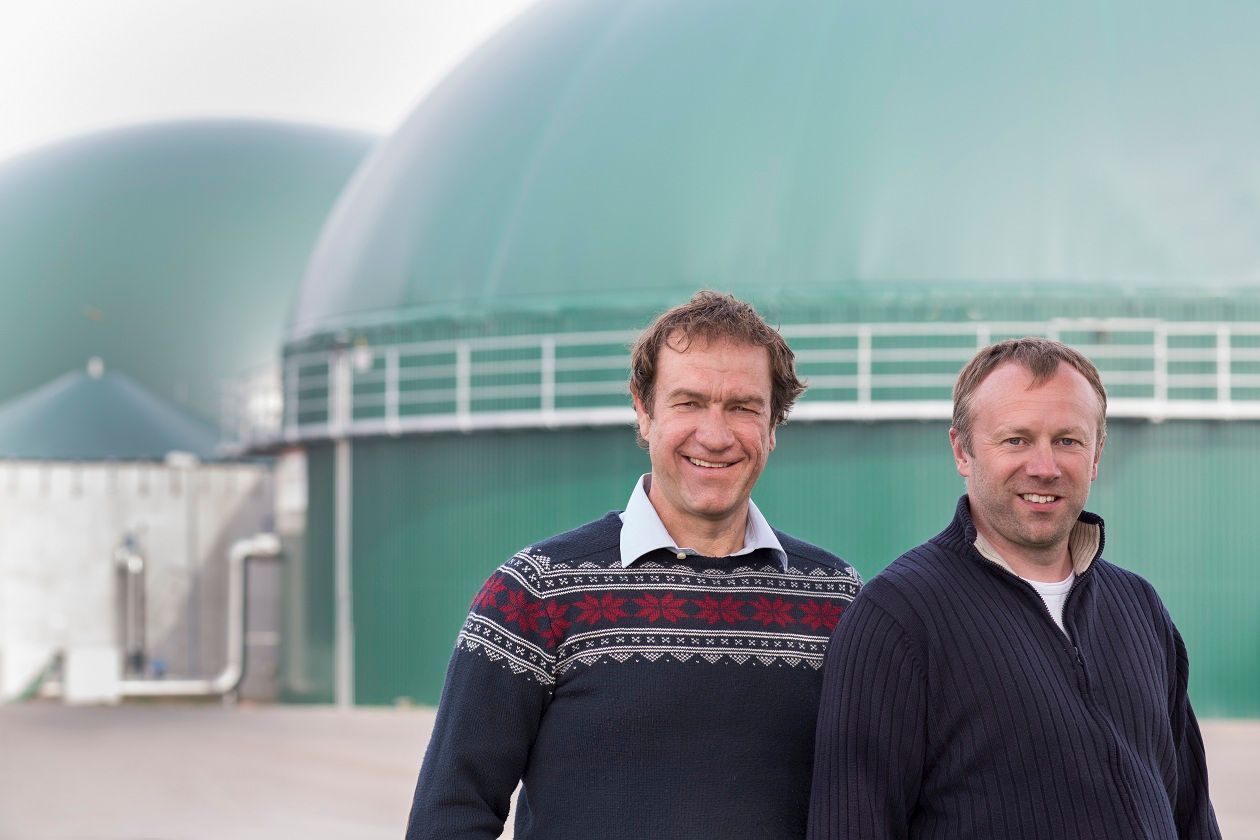

“When our biogas power plant was under construction, people wondered why we were installing 4 MW CHPs but only kept the motors running for a few hours a day” says Onno Wilberts while pointing at the three combined heat and power (CHP) units at the biogas power plant he operates with his business partner Guido Koch.

Table of Contents

“We needed to do a lot of explaining and convincing.” Back in 2011, Wilberts and Koch were indeed pioneers in the German biogas industry. Their objective: A highly flexible biogas power plant that can help stabilize grid frequency and follow a peak-load operation schedule that is tied to the current price of power on spot markets.

“To put our plan into action, we needed a reliable market partner who could place the flexibility of our power plant on the electricity market,” Koch recalls. “Next Kraftwerke offered the competence we were looking for. We especially value the close cooperation and excellent support they provide.” Today, the power plant is controlled via a remote control unit, and its power production is shifted up and down as often as 20 times a day. The power plant can be controlled in 15-minute increments based on current prices on the spot market.

But also the transmission grid operators benefit from valuable control reserve which the biogas unit provides through Next Kraftwerke's Virtual Power Plant. The power plant runs on an average electric capacity of 1.2 MW, while the installed capacity is nearly 4 MW. Additionally, the power plant’s storage encompasses 14,000 m3. With this immense flexibility, it can help compensate fluctuations in the national power grid, caused by intermittent PV and wind infeed, sudden changes in electricity consumption, or even unplanned downtimes of conventional power plants.

The input material is just as versatile as the power production itself: Wilberts and Koch use a mixture of manure, chaff and corn. The power plant also adjusts to seasonal conditions by producing more or less power based on the amount of silage. “Through an operation that is tied to the price of power, and the flexibility of the power plant itself, we can achieve the highest profits. We decide how much power to produce based on the electricity prices and the substrate prices.” In addition to the price-led power production, the flexibility of the power plant is an advantage when it comes to repair or maintenance work. Inavoidable downtime is compensated later without impacting earnings. "This argument has also been accepted by the financing bank, since deductions are usually calculated for non-availability of a biogas plant," stresses Onno Wilberts.

Despite the flexibility of the system at various levels, Onno Wilberts and Guido Koch consider it important that system operation and earnings remain predictable and stable. They have therefore agreed with Next Kraftwerke on a flat-rate remuneration for the flexibility of their plant. This remuneration is based on the availability of each individual flexible kilowatt of the unit. Could this be a model for the entire industry?

Facts & Figures

| Capacity in kW: | 1.560, 1.560, 800 kW |

| Gas storage capacity: | 14.000 m³ |

| Applied products: | Balancing Energy, Market Premium Model, Peak load operation |

More Information and Services