A storm turns to gas

Winter storm Axel, which set the current wind energy record in Germany, was also the source of a large wind power excess in Germany – and a considerable amount of hydrogen gas for the municipal utility company in the town of Hassfurt. There, the power-to-gas (PtG) installation, owned jointly by the city utility and Greenpeace Energy, stored the excess and particularly cheap wind energy in a matter of seconds as hydrogen wind gas.

Our Virtual Power Plant (VPP) controlled the entire process on the ground. We spoke with our PtG specialist in Cologne, Max Fuhrmann, about this particular event.

Christian Sperling: Max, we recently set a new wind energy record in Germany with 36,000 megawatts. Can Hassfurt cover its heating needs until spring?

Max Fuhrmann: We certainly created a lot of hydrogen, but it wasn’t quite that big of a leap. At the civic wind energy park in Hassfurt, strong winds occur often. They are, however, unpredictable, but that is exactly what allows us to demonstrate how flexibly the PtG installation responds to these remarkable wind events and converts the excess wind energy into gas.

Christian: How does the PtG plant in Hassfurt store excess wind energy?

Max: The PtG plant converts the excess energy into oxygen and hydrogen using electrolysis - the same principle we know from chemistry class. The combustible hydrogen is stored in a tank and gradually added to the city’s natural gas mix.

Christian: What would happen with the excess energy if we couldn't convert it to gas?

Max: We would have to remove the excess energy from the distribution grid and reroute it to the transmission grid, where it would be sold or exported. Hassfurt usually isn’t the only place affected when the wind is blowing hard, so we’d have to sell the energy very cheaply or even at a negative price.

Christian: I see. Then is it particularly important that the PtG plant reacts quickly to market price signals from the Virtual Power Plant?

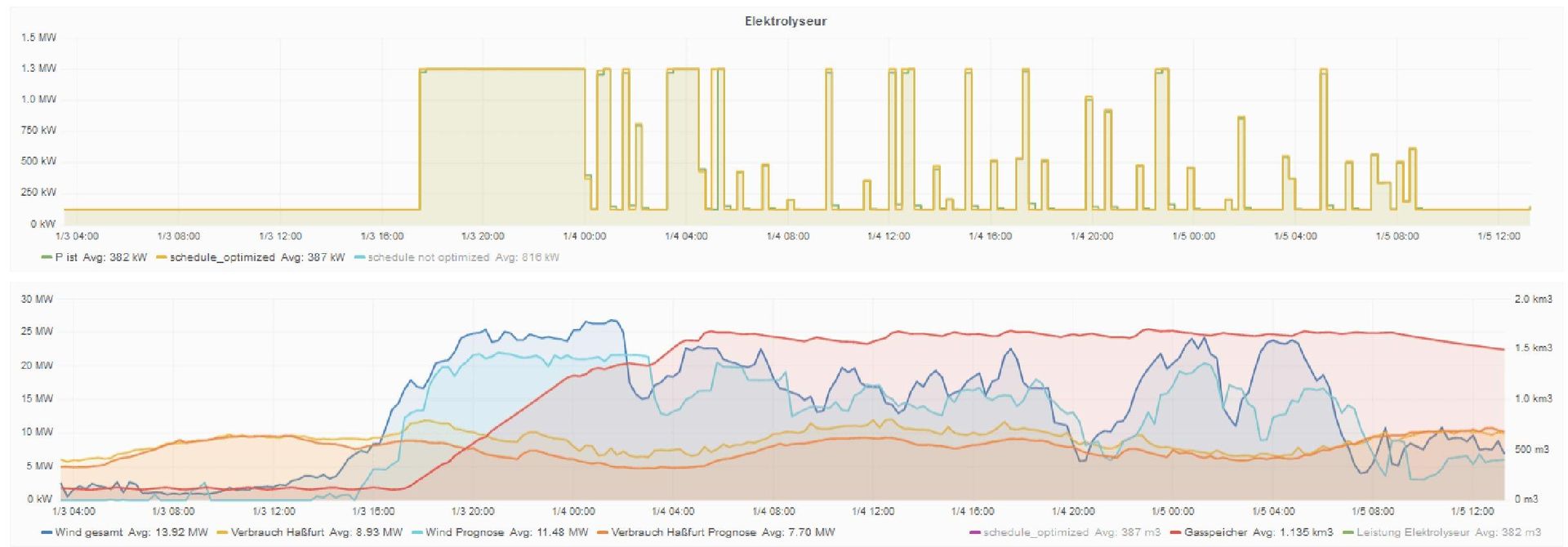

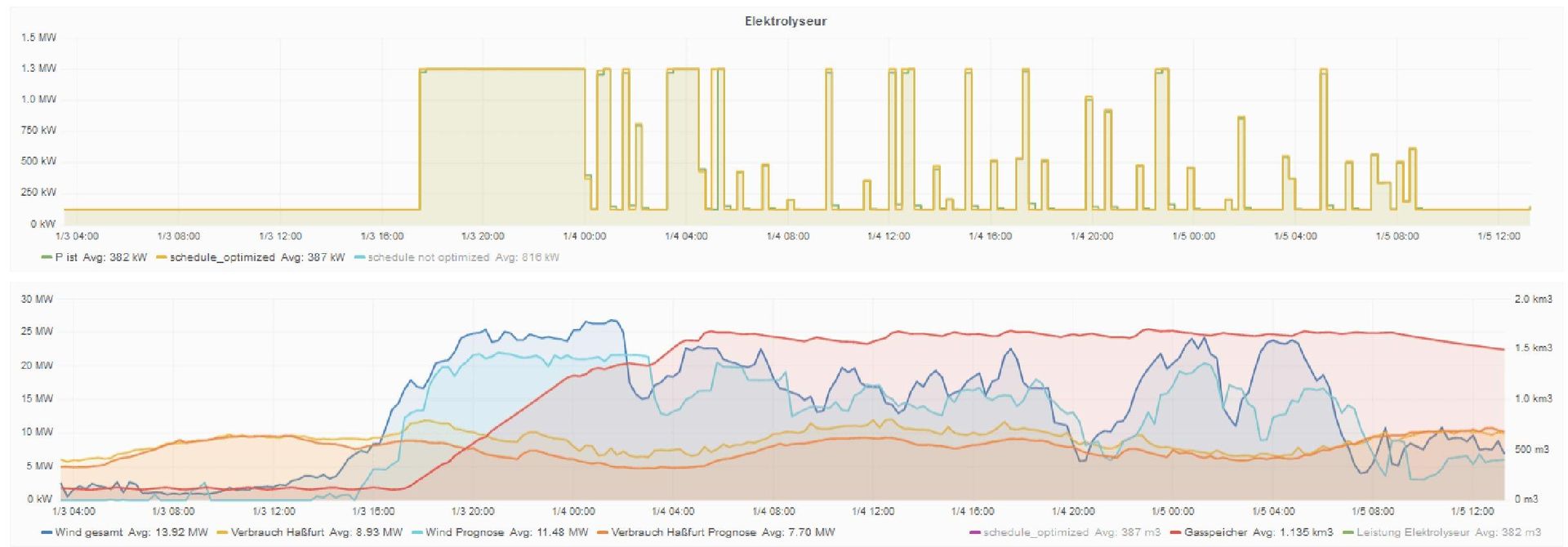

Max: Absolutely. We only create hydrogen where there is a lot of wind, and when the energy generated by the wind cannot be completely used by consumers in Hassfurt’s distribution grid. In addition, producing gas is only worth it when the market energy price falls particularly low. Once all these conditions have been met, the central system gives a start command until the price starts to rise again as the wind dies down. Then the electrolysis is stopped. You can see this particularly well on the chart.

Christian: What exactly do the curves on the chart tell us? It looks pretty complicated...

Max: It’s not so difficult. On the upper part of the chart, the green line shows the operation of the electrolysis mechanism. We can go from a minimum load to full operation in 15 seconds, which is why the curve is so square. The yellow line is the optimized operation plan, which the PtG plant receives from the Virtual Power Plant in Cologne. Both lines, with one small exception, are congruent. This is an indication that the interaction works quite well.

Christian: What about the graphs on the lower part of the chart?

Max: The red and the blue graphs are the important ones. The blue graph shows the actual wind input, and the red graph is the gas storage level in Hassfurt.

Christian: Looks like the wheels were really in motion on January 3 at about 4 p.m...

Max: Correct. Our Virtual Power Plant in Cologne registered the quickly rising level of wind energy, which receives data from our own prognoses and as well as live data from the many plants in our control system linked across Germany. It takes a bit of time for the market to react to the increase in energy with a lower price, and we’ve established a threshold where gas production begins. The threshold was reached at about 5 p.m., and the electrolysis mechanism receives the signal to start gas production completely automatically. From that point until about midnight, the plant was producing hydrogen because of the rising level of wind power (blue line). The gas storage level rises quickly as well (red line).

More to read

Christian: Why did production stop at midnight? There seemed to be more storage capacity available.

Max: Our prognosis data showed a decrease in the wind - as a precaution, the Virtual Power Plant tells the plant to stop production. When the wind took a little while longer to die down and the market price remained low, gas production was started up again on short notice. At about 2:30 a.m. the wind was blowing stronger again and we were producing gas until the storage was full. We could have produced much more gas that night, but the plant has a limited capacity for storing gas, and the natural gas network can only accept so much hydrogen.

Christian: Understood... then the “irregular” intervals when the plant is switched on and off are not only determined by the energy price but also the technical limitations of the natural gas grid?

Max: Exactly. This meant there were times when we couldn’t produce as much gas as we wanted to, such as January 5 at around midnight during another increase in wind with low prices. Unfortunately, we couldn’t increase the hydrogen input at that time. To keep from diluting the natural gas, the plant can only add a certain amount of hydrogen into the natural gas mix.

Christian: All right, so it isn’t perfect, but you're on the right track?

Max: Absolutely. The plant reacted splendidly to storm Axel, especially on January 3. By working with our Virtual Power Plant, the power-to-gas plant was able to provide flexibility, ease the load on the distribution grid, and convert the wind energy in a sensible way. In the future, we of course want to further optimize the off and on periods in varying winds and the fluctuating prices that result. That would let us align gas production with the energy price developments as closely as possible.

Christian: What about the storage capacity?

Max: If you expand the storage capacity, you can of course store more excess wind energy as gas. To increase the hydrogen input into the gas mix, you can chemically or organically put the hydrogen through a methanation process, or increase the proportion of hydrogen in the gas mix.

Christian: Seems there will be plenty to report on this project in the future...

Max: Correct. It’s really a lot of fun, especially when we’re working here with a cross-departmental team of energy traders, IT specialists, and connection technology experts, along with our partners from the Hassfurt utility department and Greenpeace Energy. There’s still a lot there - for more blog posts, too!

Christian: Max, thanks a lot for your time and we wish you lots of luck and lots of fun with your project - we’ll look forward to more exciting stories!

More information and services